Implementing Diversey DryFormance water-free conveyor lubrication technology on food and beverage packaging lines will deliver a variety of benefits, at both site and corporate level, against the Safety, Health, Environment and Quality (SHEQ) agenda.

Improved Health & Safety

The number one reason why customers choose Diversey DryFormance is the improvement to health and safety.

In the food and beverage industry, the rate of injury due to slips, trips and falls is above the Manufacturing sector average and represents the 2nd biggest cause of injury. Some 90% of slips are a result of wet or contaminated floors.

DryFormance oil-based lubricant uses zero water in the lubricating process. It is applied in optimized volumes directly to the conveyor belt using a unique brush and inserts application method, ensuring no excess ends up on the floor and creating a safer working environment.

By removing lubricating water from the packaging conveyors, the conditions for biological growth are reduced, creating a more hygienic operating environment. Wet carryover areas (eg pasteuriser outfeed) can be targeted with specific drainage and cleaning.

Reduced Environmental Footprint

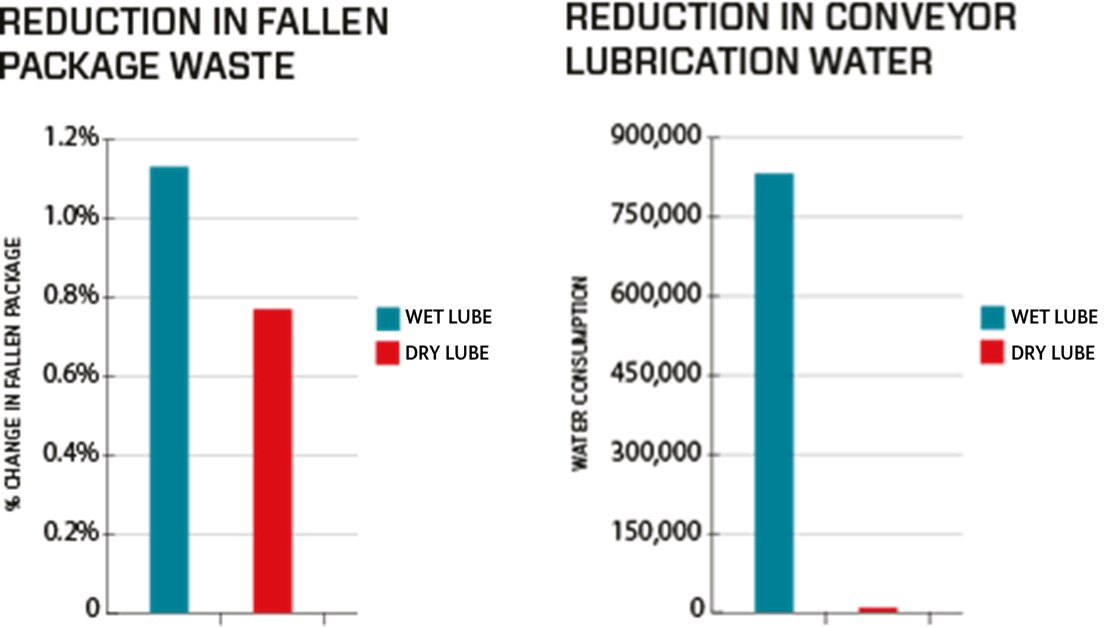

Reduced Water Consumption

A high volume, high speed can line will typically use up to 2.5 million litres of water per year to lubricate conveyors. A returnable glass bottle line can use three times as much. With DryFormance, water usage is reduced by up to 100%. When implemented as part of a global initiative, the impact could achieve a water:product ratio reduction of 0.1HL/HL.

Reduced Waste-Water Treatment

DryFormance lubricants add no load to effluent as a result of the formulations and the distribution methodology. Any trace amount that may be found in waste-water after line cleaning does not require further treatment and poses no contamination risk.

Reduced Energy Usage

Data collected at customer sites indicates that there is a 10% reduction in energy usage per conveyor motor in plastic belt operations and 7% with stainless steel. This is a result of the DryFormance lubricant and application method which reduces friction between the product and the conveyor belt and between the conveyor belt and the wear strip. This reduces the ‘load’ on conveyor motors which, in turn, use less energy.

Reduced Primary Container Waste

Many bottles, cans and cartons that are damaged during the filling and packaging process cannot be recovered and are lost to waste. DryFormance controls friction on a zone-by-zone basis depending on the characteristics of each zone, helping to manipulate product traffic, improve package handling and, as a result, reduce fallen, wasted containers.

Reduced CO2 Emissions

The carbon footprint is reduced in the following ways when implementing DryFormance:

- 0.95kg of CO2 will be saved per litre of wet lubricant saved from effluent treatment.

- 0.527kg of CO2 will be saved per every 1kWh saved as a result of reduced motor power.

- CO2 emissions generated from recycling wasted containers, and manufacturing replacements, are reduced.

Improved Asset Care

By removing water or a wet lubricant solution from the packaging lines, mechanical components within the conveyor chassis deteriorate slower, reducing unplanned downtime, maintenance and replacement frequency. Additionally, factory floor degradation or removal of safety markings caused by puddles of lubricant overspill is eradicated.

Diversey’s DryFormance lubricants have been formulated specifically for use with food and beverage packaging line conveyor belts and contain anti-wear additives. Used in conjunction with the DryFormance distribution system and application method, the lubricant acts as a layer of protection around the belt and has been proven to improve plastic chain life by at least 200%. In some cases, customers have not changed their belts for over ten years.

Lower Total Cost Of Ownership

All of the benefits outlined above have a financial upside which will deliver a lower total cost of ownership over the duration of the DryFormance contract. DryFormance is used in can, carton, PET, keg and glass packaging lines, with plastic and stainless steel belts. Using a few pieces of operating data, our team can calculate the expected benefits from implementing a system at your site.